Technology

Cutter Exchange

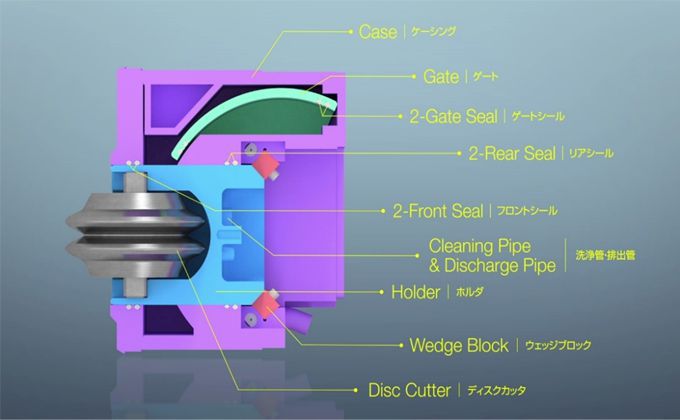

Slide rotary type disc roller cutter exchange device

When excavating a bedrock section, it is possible for operator to safely exchange the disc roller cutter from inside TBM (inside cutter frame) under atmospheric pressure without working in dangerous place such as the cutting face side or cutter chamber.

Features

- The disc roller cutter exchange device can be installed in any place of cutter frame.

- It can minimize the total number of the exchange device by employing twin ring type disc roller cutter.

- It can ensure effective opening for soil intake by reducing frame numbers.

- It can resist to high pressure

- Disc roller cutters can be exchanged under 2.0 MPa water pressure.

- It can be replaced to cutters that can excavate soft ground.

- it is applicable to complex geological condition (mixture of rock and soft ground) .

- Equipped with clogging consolidation prevention mechanism and disc roller cutter wear detection mechanism

- Prevents clogging inside the cutter holder by using limiting plates for avoiding soil inflow and by discharging additive.

- Equipped with magnetic wear detection sensor to prevent uneven wear, and mechanical wear detection method.

- High maintainability

- Main parts of disc roller cutter exchange device (ball gate and holder) can be exchanged under atmospheric pressure without ground improvement.

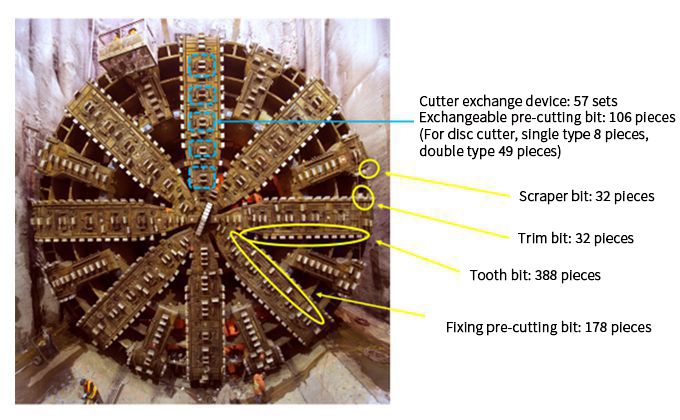

Arc gate type cutter bit exchange device

Features

- Cutter bits can be safely exchanged under atmospheric pressure.

- The arc gate has a structure that pulls it backward when it is closed, so even if the water pressure is high, it is possible to stop water reliably by utilizing external pressure.

- Since the gate seal is separated from the seal surface when opening and closing, the operation is smooth and the risk of damage to the seal is low.

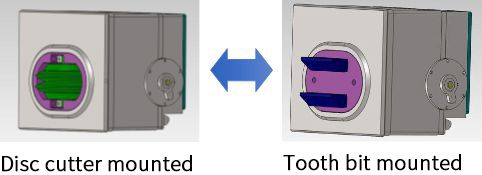

- It has compact structure, suitable for equipment that can exchange large excavation tools such as disc cutters.

- By injecting a filler (grease, etc.) into the gap when the cutter bits are pulled out, the collapse and inflow of the ground are prevented.

- It is applicable to various excavation tools, for example, the disc cutter and tooth bit can be exchanged.

- The gate can be removed and exchanged even if the seal is damaged.

Arc gate type cutter bit exchange device

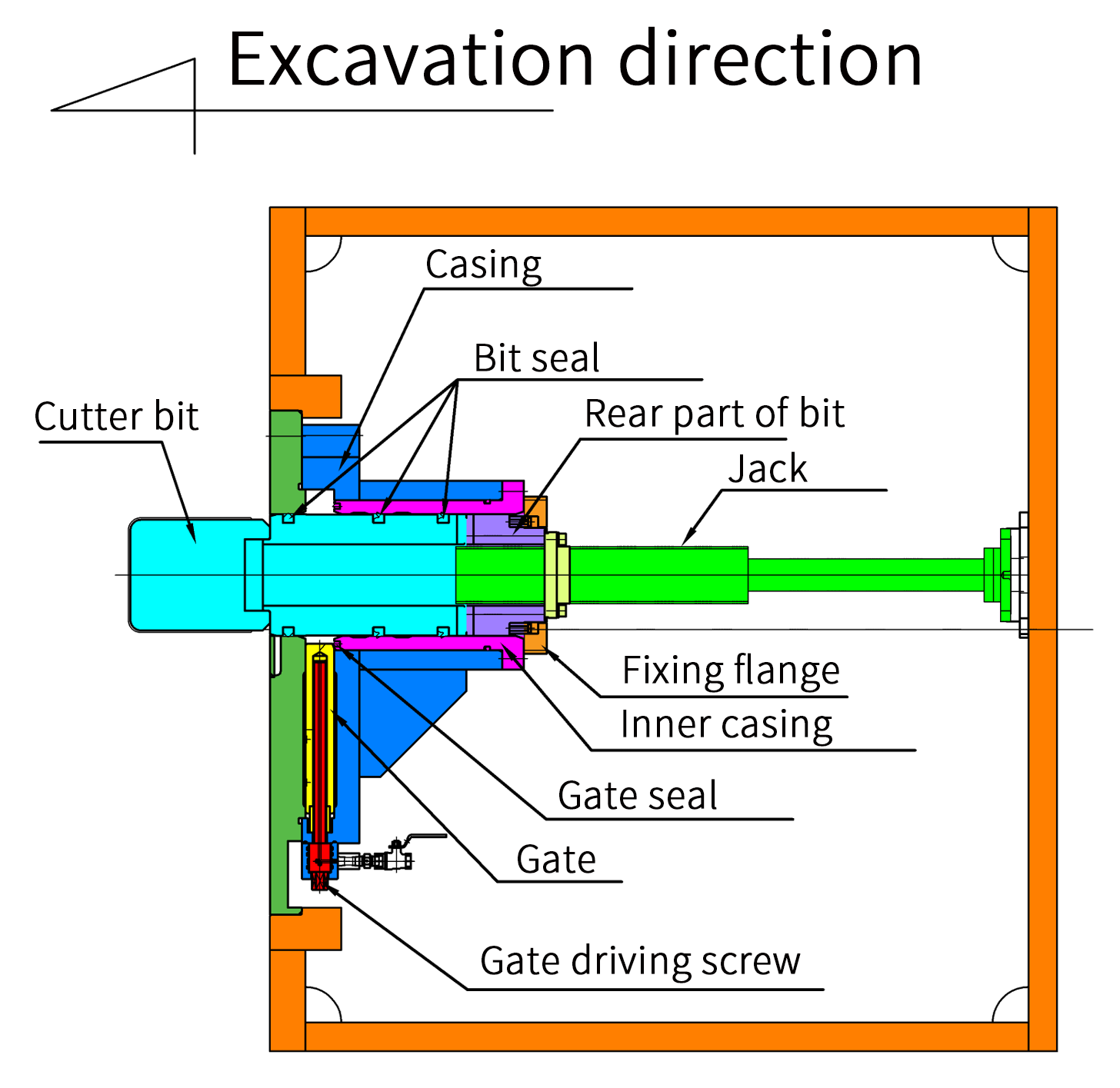

Double casing slide gate type cutter bit exchange device

Features

- Cutter bits can be safely exchanged under atmospheric pressure.

- By retracting the inner casing when opening and closing the gate, the gate does not come into contact with the seal, so the gate operates smoothly and the risk of damage to the seal is low.

- Water can be stopped reliably by pressing the gate seal against the gate after the gate is closed.

- Since it has a compact structure, and if it is applied to multiple structure, it is possible to arrange the bits close to each other.

- By injecting a filler (grease, etc.) into the gap when the cutter bits are pulled out, the collapse and inflow of the ground will be prevented.

- It is easy to maintain because the main parts including the gate can be replaced.

- If the gate seal is damaged, it can be exchanged by pulling out the inner casing.