Technology

High Speed Excavation

Simultaneous excavation (long stroke type)

The excavation and segment assembly can be performed at the same time by extending the shield jack stroke and the space of the tail part with special hydraulic control system.

Furthermore, by incorporating a semi-automatic erector that automatically transport to the segment assembly position, it can improve construction efficiency and safety.

| Year of delivery / Place of delivery | 2009 / Tokyo |

| Construction name | Central Circular Shinagawa Line Shield Tunnel (North) Construction |

| Owner name | Metropolitan Expressway |

| Contractor name | Kajima / Kumagai / Penta Ocean JV |

| TBM outer diameter | 12.55m |

| Excavation distance | 8,030m |

| Features | Mechanical cutter bit exchange device, vacuum erector |

Simultaneous excavation (double jack type)

By installing advance jacks and erection jacks on the inner shell, the machine can carry out excavation and segment assembly at the same time.

| Year of delivery / Place of delivery | 2003 / Tokyo |

| Construction name | East-West Linking Gas Pipe Line Construction |

| Owner name | Tokyo Electric Power Co., Inc. |

| Contractor name | Kajima / Nishimatsu / Obayashi JV |

| TBM outer diameter | 3.62m |

| Excavation distance | 9,030m |

| Features | Maximum monthly advance 1,168m, average monthly advance 665m |

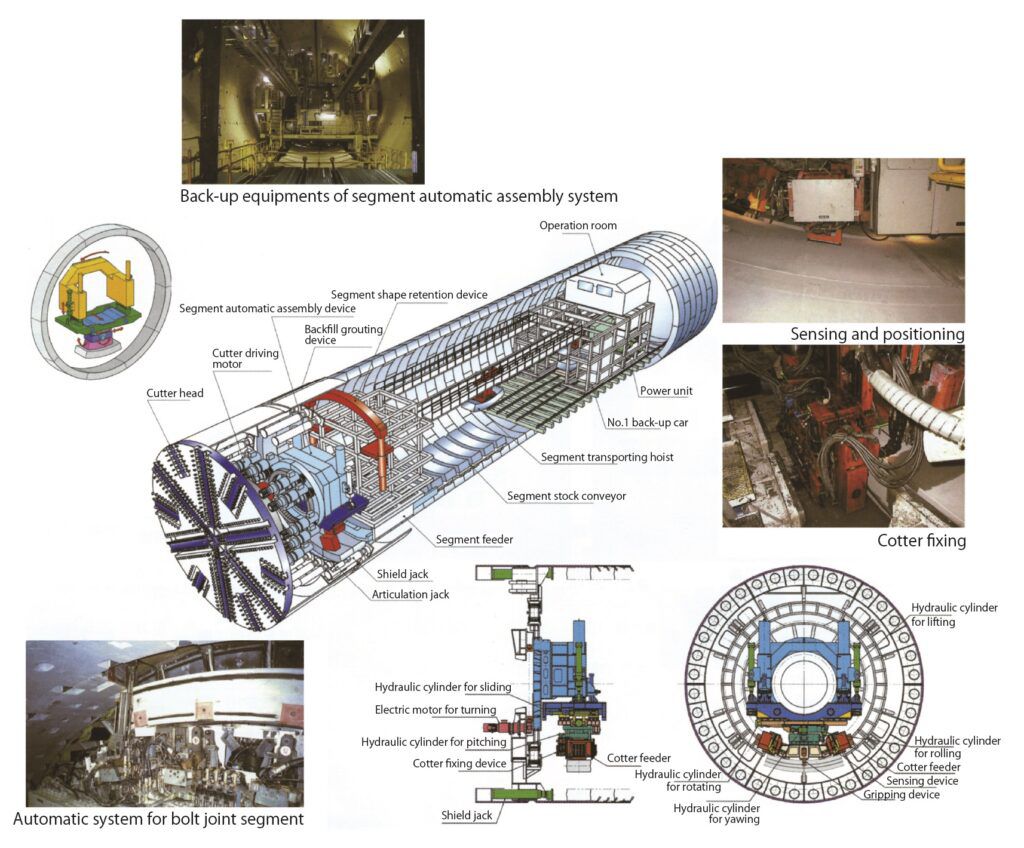

Segment automatic assembly system

The segment automatic assembly system automates a series of operations such as segment transport, supply, gripping, positioning, and fastening. It is applicable to various segment joint types (short bolts, long bolts, cotters, etc.) and can improve assembly quality and safety, especially for large diameters.